/0/1618/coverbig.jpg?v=20171123164849&imageMogr2/format/webp)

THE origin of glass is lost in antiquity. Pliny, indeed, ascribes its discovery to certain Ph?nician mariners who, being shipwrecked upon a sandy shore, used a block of the natron which formed their cargo to support a pot which they were putting over an improvised fire. The heat fused the sand with the natron, and lo! the glass was discovered in the ashes.

Old Glass and How to Collect it CHAPTER I INTRODUCTORY

THE origin of glass is lost in antiquity. Pliny, indeed, ascribes its discovery to certain Ph?nician mariners who, being shipwrecked upon a sandy shore, used a block of the natron which formed their cargo to support a pot which they were putting over an improvised fire. The heat fused the sand with the natron, and lo! the glass was discovered in the ashes.

Since, however, Pliny's authority was Rumour, and since, also, such a phenomenon is a physical impossibility-for no bonfire could produce a temperature at which sand would fuse-it is possible that Rumour in Pliny's day had a no greater reputation for reliability than in the twentieth century. But the story, if not true, is at least well invented and serves to show at how early an age in the world's history glass was known.{2}

It is more than probable that the place of its origin was Ancient Egypt, and that the Ph?nicians, who were undoubtedly acquainted with its use, drew their knowledge from the workers on the banks of old Nile. At any rate articles of glass have been discovered in tombs of the fifth and sixth dynasties-some 3300 years before Christ. This, the earliest known glass, is generally opaque, and is chiefly used to form small articles of ornament, such as beads for necklaces, etc. The "aggry" beads, found in Anglo-Saxon barrows and made in our own time by the Ashantis and neighbouring tribes, are of similar type. Some admirable specimens of ancient Egyptian glass are to be found in the British Museum. Among them is a turquoise-blue opaque glass jar of Thothmes III.-the greatest of all the kings of Egypt-dating from about 1550 B.C.

At a later date glass was extensively made in Alexandria, the sand in the vicinity being of exceptional purity and so, suitable for its manufacture. The city speedily became celebrated for the beauty of its output, and articles of Alexandrian glass were largely exported to Greece and to Rome, where also, in the space{3} of a few years, glass-houses were established; and to Constantinople, which was, in time, to become famous for the manufacture of coloured glass and of the Mosaics so dear to the Oriental taste.

The Greeks do not appear to have developed the art of glass-making at a very early age, but specimens of glass have been found in Grecian tombs, and, in the Golden Age of Ancient Greece, when art and literature reached their zenith under Pericles, glass was certainly employed for purposes of architectural decoration.

In Rome, however, the art of glass manufacture found a congenial home and was developed to a high pitch of excellence. So widespread was its use that it is a truism to say that in Rome of two thousand years ago glass was employed for a greater number of purposes-domestic, architectural, and ornamental-than it is to-day, even though the glazing of windows was in its infancy and the use of the material for optical purposes was scarcely known. In effect, coloured and ornamental glass held much the same place in the Roman household that china and earthenware do among us to-day. Glass was used for{4} pavements and for the external covering of walls. The Roman glass-workers were particularly happy in their combination of colours, both by fusing together threads of various colours, or by fusing masses, so as to imitate onyx, porphyry, serpentine, and other ornamental stones.

The most interesting of all was the famous cameo glass. A bubble of opaque white glass was blown, and this was coated with blue and a further layer of opaque white superimposed. The outer coat of blue was removed from the portion which was to display the design, leaving the white to be carved into whatever figures the artist's fancy dictated. The finest example extant of this kind of ware is the famous Portland vase in the British Museum.

The art, thus brought to such perfection in Rome, naturally spread throughout Italy and the Roman colonies in France, Spain, Germany, and Britain. Probably workmen from the Italian cities also established the first furnaces among the lagoons of Venice, and so laid the foundation of what were to be the finest glass manufactories in the world. At the end of the thirteenth century a guild of glass-workers{5} was formed. These sequestered their craft upon the island of Murano, and there cultivated it with an increasing skill that in a brief space made Venetian glass the marvel of the civilised world. The peculiar merits of the Venetian product were grace of form and lightness of execution. Many of the vessels are surpassingly thin. The quality of the metal, however, leaves something to be desired. It is dull, frequently tinged with yellow-due to the presence of iron-or purple-the effect of too great a proportion of manganese. The workmen became so skilful that, carried away by the joie d'exécuter, they produced not only the artistic forms for which Venetian glass is famous, but all sorts of extravagances-ships, animals, birds, fishes, and so on-whose only merit was to testify to the excellence of a technique which could so triumph over the difficulties of form and material.

Meanwhile, other European nations had taken their cue from Venice, and glass-houses sprang up in various parts of the Continent, particularly in France and in Bohemia; the latter, indeed, speedily became the great rival of Venice.

In England, as we shall see, glass was made{6} during the Roman occupation. Under the Saxons, glass-workers were imported from the Continent, but to judge from the number and variety of the specimens found in Anglo-Saxon tombs, it is probable that it was also manufactured to an equal extent at home. During the Middle Ages the art appears to have fallen into abeyance, save in a few isolated instances to be noted later, but in the sixteenth century the custom of using glass vessels was introduced from France and the Low Countries, most of the pieces being imported from Venice. To prevent the money thus expended from leaving the country, efforts were made about the middle of the century to establish the art by the aid of workmen from Murano, and the history of glass manufactured in England may be said to have fairly begun. It was undoubtedly stimulated by the religious persecutions on the Continent, particularly the Spanish Terror in the Netherlands, for the Low Countries were seriously endeavouring to rival Murano in the art, and the craftsmen who fled for refuge to England undoubtedly did much to develop their trade in the country of their adoption, as did the Huguenot refugees at a later period.

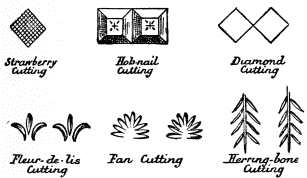

In the seventeenth century the whole process was revolutionised by the introduction of a large proportion of oxide of lead, making what is technically known as "flint" glass-a glass much more brilliant than any other, a quality due partly to its transparency and partly to its increased refractive power, which renders it specially fitted for "cutting"-a process which enhances its beauty by increasing the number of ways in which the light rays falling on the glass are dispersed. The discovery has given English glass a well-deserved pre-eminence for beauty of metal-a pre-eminence which the glass-cutters of the eighteenth century admirably{8} sustained by the excellence of their work.

All this time the art of glass-making on the Continent had been developing. In particular, the Venetian workers at Murano had perfected the art of colouring and enamelling glass-a result which was later to have its influence upon English artists. An admirable example of what they achieved in this direction is an old spinet in the South Kensington Museum, which once belonged to Queen Elizabeth of Bohemia, the daughter of James I. Whatever its merits as a musical instrument, its once gorgeous gilt crimson leather case hides an interior of the utmost interest to students of glass, for the interior of the lid is panelled into eighteen divisions, each representing some classical subject-Narcissus, Daphne, Andromeda, Argus, etc.-admirably done in coloured glass. The front of the keyboard, the stretcher bar and the keys themselves are also elaborately decorated in similar fashion with coloured glass, silver or enamel. The keys are covered with ornaments in coloured glass, the accidentals being faced with blue and white striped glass and the naturals being fronted with the same.{9}

Although it is no part of the purpose of this book to deal in detail with the technical side of the manufacture of glass, yet some few words as to the nature of the material with which we are dealing are not only desirable but essential to the proper understanding of its various qualities and kinds and the different stages of its manufacture.

The scientist will tell us that glass is a double silicate, being compounded of a silicate of sodium (or potassium) and a silicate of lime. For the benefit of non-scientific readers, we may remark that a silicate is a chemical compound formed when silica combines with an alkaline substance like lime, soda, or potash. Silica is probably the most widely distributed substance in nature. Silicate of alumina is, for example, the basis of all clayey soils, and silica, in the pure form of quartz, is the chief constituent of the sand of the sea and of all those rocks which are known as sandstones. Rock-crystal, amethyst, agate, onyx, jasper, flint, etc., are all varieties of silica. Crystalline silica is hard enough to scratch glass-a fact utilised, as we shall see, in the sand-blast which is used for the purpose of engraving patterns on glass. Silica{10} is fusible only at a very high temperature, but readily combines with alkaline substances to form soluble silicates, which are known in commerce as soluble glass, or water-glass, because it dissolves readily in hot water. Water-glass is used in making artificial stone, in coating stone surfaces, e.g. walls of buildings, etc., to preserve the stone from decay under the weathering influence of the atmosphere, and in the manufacture of cement.

Ordinary glass has many valuable properties which make it of great importance in the arts and manufactures. Among these may be mentioned the fact that it can be made to take any shape with ease. It resists the action of all ordinary acids, and hence is of the utmost value to the chemist and the chemical manufacturer. Hydrofluoric acid alone attacks it, by combining readily with its silica and so dissolving it. For this reason, hydrofluoric acid is used in etching on glass. Again, glass is cheap, being literally made from the dust of the earth; it is transparent, and so can be used in buildings, transmitting light whilst protecting from the inclemency of the weather. Its transparency, too, combined with its high refractive power,{11} make it of inestimable value in the manufacture of optical instruments. It is this high refractive power, too, which gives to cut glass its beautiful lustre and sparkle, and one aim of the glass-founder is to increase this refractive power and so enhance the brilliancy of his product. If glass could be made which would refract light to the same extent as the diamond does, it would exhibit the same "fire" as the king of gems. It is hard and close in texture, and so is capable of taking a high polish. Its great drawback is its brittleness, but this can be reduced to a great extent by immersing it, whilst red-hot, in a hot bath of paraffin oil, wax, or resin. A tumbler of glass so "tempered" may be dropped on the floor without breaking.

It may be added, as a matter of common interest, that this brittleness is largely a result of the fact that glass is an extremely bad conductor of heat. Because of this, a mass of molten glass, when cooling, becomes set on its outside surface long before the interior has become solidified; hence the solid exterior prevents the molecules of the interior portion from contracting. As a result, a condition of strain is established, the interior molecules{12} tending to contract, while the exterior tends in the opposite direction; consequently a very slight blow is enough to cause a fracture.

Varieties of Glass.-As we shall frequently find it necessary to refer to the various kinds of glass, it may be as well at the outset to attempt to give a clear idea of their differences and of the meanings of the various terms employed in describing them.

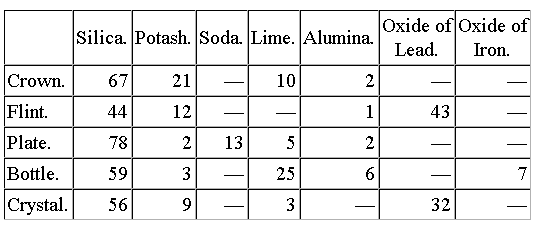

As regards quality, the chief kinds are crown glass, flint glass, plate glass, bottle glass, and crystal glass, and the differences in composition may be conveniently expressed in the form of a table:-

Continue Reading

Continue Reading

/0/1618/coverbig.jpg?v=20171123164849&imageMogr2/format/webp) Old Glass and How to Collect it

J. Sydney Lewis

Literature

Old Glass and How to Collect it

J. Sydney Lewis

Literature

CHAPTER I INTRODUCTORY

19/11/2017

CHAPTER II EARLY ENGLISH GLASS

19/11/2017

CHAPTER III EIGHTEENTH-CENTURY GLASS

19/11/2017

CHAPTER IV MEMORIAL GLASSES

19/11/2017

CHAPTER V BRISTOL AND NAILSEA GLASS

19/11/2017

CHAPTER VI IRISH GLASS-CORK AND WATERFORD

19/11/2017

CHAPTER VII CURIOUS AND FREAK GLASSES

19/11/2017

CHAPTER VIII FRAUDS AND IMITATIONS

19/11/2017

CHAPTER IX SOME HINTS TO COLLECTORS

19/11/2017

/1/107856/coverorgin.jpg?v=47c59efb9a2e1190e061295bcc967527&imageMogr2/format/webp)

/0/77336/coverorgin.jpg?v=b0064f360b5858825f4c662e7fe502c8&imageMogr2/format/webp)

/1/102860/coverorgin.jpg?v=fd4279179a94dd229627ce7640bf190d&imageMogr2/format/webp)

/0/64082/coverorgin.jpg?v=3b6497ddf8ecfa841031756b6c683c74&imageMogr2/format/webp)

/1/107281/coverorgin.jpg?v=3425e5f3c3e85939e0b5df5ee05b3256&imageMogr2/format/webp)

/0/73838/coverorgin.jpg?v=13386996a09e7a2f9334fc224055a59a&imageMogr2/format/webp)